Magnetic Drive Solutions

Application

For petrochemical, pharmaceutical, film, electroplating, nuclear power and other industries, the leakage of corrosive, flammable, explosive, toxic, and precious liquids will cause environmental pollution. Magnetic transmission couplings can effectively solve the leakage problem.

Structure and principle

The magnetic transmission coupling is a non-contact coupling. It is generally composed of two magnets inside and outside. The two magnets are separated by an isolation cover in the middle. The inner magnet is connected to the driven part, and the outer magnet is connected to the power part.The biggest feature that it turns the dynamic seal into a static seal to achieve no leakage . Therefore, it is widely used in occasions with special requirements for leakage.

Comparison of Sequoia Cobalt and NdFeB Magnets

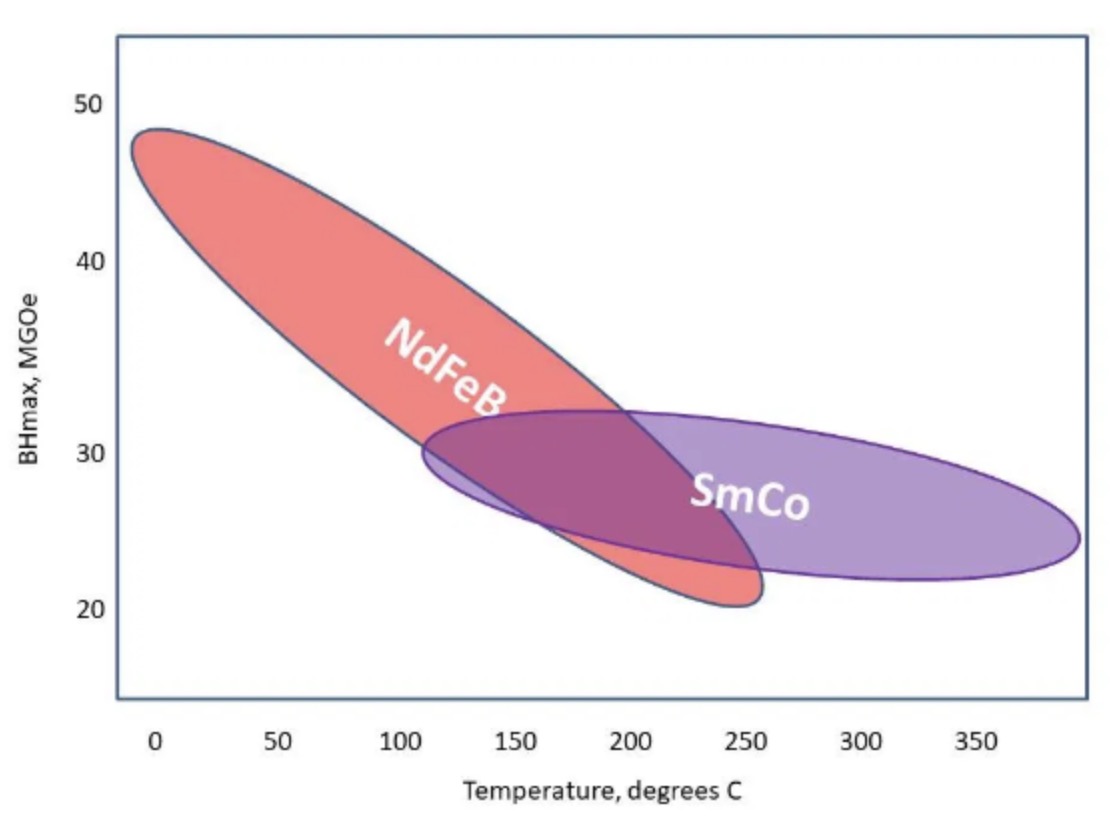

1.Magnetism: NdFeB is stronger

2.High temperature resistance: NdFeB magnets can withstand a maximum temperature of 220 degrees. Samarium cobalt magnets can reach a temperature of 350 degrees

3.Stability: The temperature coefficient of remanence of NdFeB is relatively large, while SmCo is very low. At the same temperature, the demagnetization of SmCo is much less than that of NdFeB. In addition, NdFeB must be electroplated, otherwise it will be easily oxidized, corroded and weathered.

4.Magnetic energy product

magnetic material

The second-generation permanent magnet material is samarium cobalt (SmCo5, Sm2Col7), its magnetic properties are greatly increased compared with ferrite materials, it can transmit larger torque.

The rare earth neodymium iron boron (NdFeB) permanent magnet material has a maximum energy product (BH) max of 286 6kJ/m. Neodymium iron boron (NdFeB) not only has better magnetic performance ratio, but also has good processing performance, which can be used for cutting and drilling.